|

Frequently Asked Questions

|

| Q1: |

What are StimuZyme™ & KleenZyme Enzyme Concentrates?

|

| A1: |

StimuZyme™ and KleenZyme are biological liquid enzyme solutions that are manufactured in a proprietary process using an activator of very select microbes blended in a high carbohydrate fermentation process. After production of the specific StimuZyme™ or KleenZyme enzyme solutions, the high concentration enzyme solution is blended with other ingredients to produce a final concentrate that reduces the adhesion of oil to solids.

|

| Q2: |

How does KleenZyme reduce the adhesion of oil to solids during environmental treatments?

|

| A2: |

KleenZyme allows solids to be cleaned and removed from the oily sludge, increasing the rate of water and oil separation and increasing the mobility of oil removal from the pits, tanks and pipelines where sludge has been stored.

|

| Q3: |

How does StimuZyme™ reduce the adhesion of oil to solids to improve the rate of production from oil wells?

|

| A3: |

StimuZyme™ increases the mobility of the oil near the wellbore by removing the damage caused by oil clogging, which has restricted either perforation or openhole flow channels, thereby improving and clearing flow through gravel packs, tubulars and flowlines.

|

| Q4: |

Can Stimuzyme™ be used in enhanced recovery operations (EOR) for the reservoir?

|

| A4: |

Waterflood studies of cores prove that StimuZyme™ reduces significantly the residual oil left behind the flood front. Laboratory analyses prove that this reduction in residual oil is primarily a result of the presence of StimuZyme™ in the reservoir making the reservoir more water-wet. The oil mobilizing effect has been proven to persist with StimuZyme™ at low concentrations in the high pressures and temperatures of the reservoir. Oil that was trapped coating reservoir rock is released by breaking adhesion to reservoir rock. China has been using our products for years and consistently records a 25% increase in efficiency within the waterflood reservoir PLUS very substantial and long term EOR after the introduction of StimuZyme™ into existing operations.

|

| Q5: |

What are enzymes?

|

| A5: |

Enzymes are non-living protein catalysts that catalyze chemical reactions without being consumed in the reaction.

|

| Q6: |

What happens to the microbes used in the manufacturing of StimuZyme™ or KleenZyme after the manufacturing has been completed?

|

| A6: |

The microbes remaining in the enzyme solution are environmentally safe; however, these microbes are eliminated as a safety precaution when the manufacturing process is completed.

|

| Q7: |

How safe is StimuZyme™?

|

| A7: |

StimuZyme™ is environmentally friendly and non-flammable. Although StimuZyme™ is also non-pathogenic and biodegradable, StimuZyme™ should not be ingested. If StimuZyme™ is spilled on bare skin it should be immediately flushed off with water. StimuZyme™ is slightly acidic with a pH of about 5 similar to tomato juice.

|

| Q8: |

What case histories do you provide for the applications for StimuZyme™?

|

| A8: |

StimuZyme™ has been used for commercially stimulating increased production from oil from wells located in the USA, Venezuela, Indonesia and China. See the Case Histories page for some examples.

|

| Q9: |

What case histories do you provide for the applications for KleenZyme?

|

| A9: |

The earliest applications of KleenZyme were used to break the adhesion of oil to solids; increase the rate of separation of oil from water and increase the mobility of the oil. Many successes were attained in the field such as 1) increasing the rate of oil recovery from slop oil tanks in Disposal Water Plants south of San Antonio, Texas, 2) the recovery and separation of oil, water, and solids from radioactive oily sludge (a Paper was presented at 1994 Petrosafe Conference by Source Environmental Services documenting a savings of over one million dollars by major oil companies in storage costs), 3) unclogging a 196 km Indonesian pipeline blocked with heavy oil and 4) accelerating bioremediation in the largest US Navy fueling station biocell at Craney Island, Virginia.

|

| Q10: |

What applications are now being developed for StimuZyme™ that have the greatest potential for future applications?

|

| A10: |

Indications for successes in EOR activities have been outstanding. Expanding the future use of StimuZyme™ for EOR applications will increase the ultimate recovery of oil production by displacing more of the oil that would have remained trapped. Future demands for increased oil production will benefit from the expanded use of StimuZyme™. Laboratory tests have been conducted indisputably proving that StimuZyme™ dramatically increases the oil displaced in cores even after conventional waterflood.

|

| Q11: |

How does StimuZyme™ work to mobilize the crude oil in an oil reservoir?

|

| A11: |

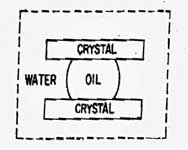

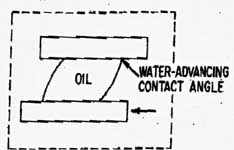

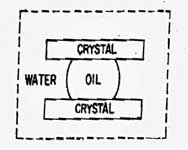

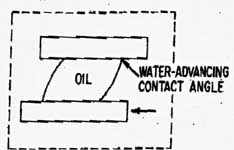

StimuZyme™ works to change the wettability of the reservoir rock from oil or intermediate-wettability to StimuZyme™/water-wet. The wettability of a reservoir is a measure of which phase, oil or water, is adhering to the reservoir rock surface. Changing a reservoir from oil wet (intermediate-wettability) to water-wet (StimuZyme™ wet) means that the oil will flow with less restriction within the reservoir. Consequently, less oil will remain trapped in the reservoir increasing the ultimate recovery of oil from the reservoir.

|

| Q12: |

In theory how does StimuZyme™ change the wettability?

|

| A12: |

StimuZyme™ works to retard the adsorption of polar compounds on the reservoir rock. Per the Classic Petroleum Engineering Monograph, “The Reservoir Engineering Aspects of Waterflooding” by Forrest Craig, Jr. it is stated that extensive laboratory experience has led to the conclusion that the nature of reservoir wettability is due to the absence or presence of polar compounds existing in minute quantity in crude oil. These polar compounds, apparently asphaltic in nature, adsorb on the rock surfaces and tend to make these surfaces oil-wet. The effects of these polar compounds depends to some degree upon the nature of the rock surface—that is upon whether the rock surfaces are predominantly silica, carbonates, or clay. M.O. Denekas produced a detailed study “Effects of Crude Components on Rock Wettability” documenting the effects on the type of reservoir rock.

|

| Q13: |

How strong can the polar compounds effect be, in crude oil?

|

| A13: |

Also described in the Classic Petroleum Engineering Monograph, “The Reservoir Engineering Aspects of Waterflooding” by Forrest Craig, Jr., it is found that in some formations asphaltic materials are so strongly adsorbed that they resist removal by normal core cleaning procedures. Examples of these are the Tensleep sandstone in Wyoming and the Bradford sandstone in Pennsylvania.

|

| Q14: |

How do you measure wettability in the Laboratory?

|

| A14: |

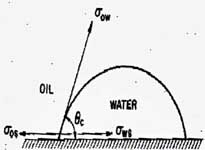

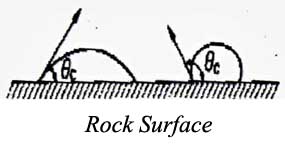

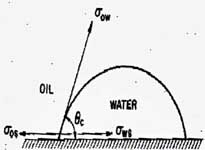

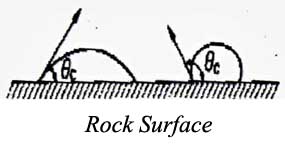

To measure the tendency of one fluid to spread on or adhere to a solid surface in the presence of other immiscible fluids, i.e. wettability, you measure the contact angle through the water phase compared to rock surface. Contact angles of less than 90 degrees indicate preferentially water-wet, whereas contact angles greater than 90 degrees indicate preferentially oil-wet. A contact angle near 90 degrees is considered intermediate-wettability.

WATER - WET OIL-WET

|

| Q15: |

What are the indications that a well will benefit from a StimuZyme™ treatment?

|

| A15: |

The well should have some historical performance to indicate that there are no mechanical problems. The well should have had strong historical oil production, but has recently experienced a precipitous drop in the oil rate. Heavy oil wells, containing high content of asphaltic polar compounds in the oil, will benefit from a StimuZyme treatment. There is a much higher increase in success (quantity of oil production) if a high rock permeability is present in the formation. The rock would pose little restriction in flow; the mobility of the oil is the primary restricting factor. StimuZyme™ is proven to greatly enhance the mobility of the oil within the formation.

|

| Q16: |

What are the protocols for a typical StimuZyme™ treatment of a single well?

|

| A16: |

Shut the well in prior to the pumping/injection operation of StimuZyme. Place a pump on the well with sufficient pressure capacity to pump the 10% StimuZyme™ solution into the oil-producing reservoir. A small quantity of diesel should be injected into the well as a pre-flush to establish the injectivity into the reservoir. The diesel will be followed by a 10% StimuZyme™ solution, which is made by mixing StimuZyme™ in a tank with the formation water before beginning pumping operations. The StimuZyme™ solution must be displaced into the formation with either diesel or production crude to assure the least amount of problems in bringing the well back on production after shut-in. The well should be shut-in for a minimum of two days to allow the near borehole temperatures to stabilize and to allow the StimuZyme™ to react with the fluid and reservoir rock. After two days, open and pump the well allowing the well to produce back the fluids that were pumped in and then stabilize. Take periodic production readings in order to validate the Enhanced Oil Recovery (EOR).

|

| Q17: |

How often are StimuZyme™ retreatments needed?

|

| A17: |

During oil well stimulation, StimuZyme™ coats the solid surfaces of the casing and the rock. From the proven field histories of previous well treatments, some wells have not required any additional treatments. The recovery of the cost of well treatment will normally occur within the first month after treatment.

|

| Q18: |

Can StimuZyme™ be used in stimulating production from wells under artificial-lift, such as pumping wells, downhole submersible pumps, or gas-lift wells?

|

| A18: |

Many artificial-lift wells have been treated successfully, with and without downhole packers. There has to be adequate reservoir pressure to support the fluid column to permit the active lift mechanism to work.

|

| Q19: |

What were the basic procedures for pipeline unclogging?

|

| A19: |

Cut pipeline in sections of length 2 kilometers or less, dependent on the feasibility. Heat KleenZyme solution to a temperature high enough to mobilize the plugged oil in line and allow the KleenZyme to get in between the pipe and oil. After KleenZyme is between pipeline and heavy oil, the oil cannot attach to the pipe to reform the plug.

|

| Q20: |

What is the temperature limit to using StimuZyme™ or KleenZyme?

|

| A20: |

The highest temperature used commercially with KleenZyme is 950 C (2030 F) in pipeline unclogging. The effectiveness of StimuZyme™ has not been tested at higher pressures and temperatures, but both are always active below the boiling temperature of StimuZyme™ & KleenZyme solution.

|

| Q21: |

What was the basic processing design for reducing the volume of Naturally Occurring Radioactive Material (NORM) waste?

|

| A21: |

Drums of NORM waste were dumped into holding tanks through/across a magnetic trap and across a very coarse screen for removal of the metals and large loose solids in the NORM. The NORM was then pumped from the holding tanks into a triple washing tank where the KleenZyme is introduced into the high shear mixing process. A screw augur allowed movement from one wash tank to the next of the oily sludge. After a thorough washing, the treated fluid mixture was fed to a double decker shaker screen. Without the KleenZyme wash, the sludge would immediately clog the screens, however, with this process at the shaker screen using a stack of coarse/ fine screens the inert Non-Hazardous Oil Waste (NOW) was separated and segregated from the NORM waste remaining, sharply reducing NORM waste volume.

|

| Q22: |

Can StimuZyme™ & KleenZyme be diluted with either fresh or highly saline water to make up working solution concentration?

|

| A22: |

The salinity of the makeup water (water to dilute StimuZyme™ or KleenZyme) does not limit the effectiveness of StimuZyme™ or KleenZyme to mobilize and remove oil from solids. When introducing the StimuZyme™ solution into an oil reservoir, it is preferred to use the formation water to dilute StimuZyme™ in order to prevent any “new-water” clay swelling in reservoir rock caused by the difference in salinity between formation and makeup water.

|

| Q23: |

Can either StimuZyme™ or KleenZyme be recycled?

|

| A23: |

StimuZyme™ & KleenZyme can be recycled and reused an infinite numbers of times because StimuZyme™ & KleenZyme are “water-borne” and never react chemically with oil. The recycle processing system should have a reservoir to capture used enzyme solution and rapidly separate the oil from the KleenZyme water-based solution. Rapid separations of the KleenZyme solution and oil have been most effected in the field using coalescence media oil-water separators.

|

| Q24: |

How are StimuZyme™ or KleenZyme shipped to my location?

|

| A24: |

StimuZyme™ & KleenZyme are liquids packaged in 55-gallon drums that are strapped together; 4 drums on each wooden pallet. For shipment to larger oil well producers or distributors the enzyme products ship in either a standard 20-foot shipping container (36 drums) or a 40-foot shipping container (76 drums). For small tests within USA, we have shipped break bulk on the 4 drums to a pallet.

|

Manufacturer

Manufacturer